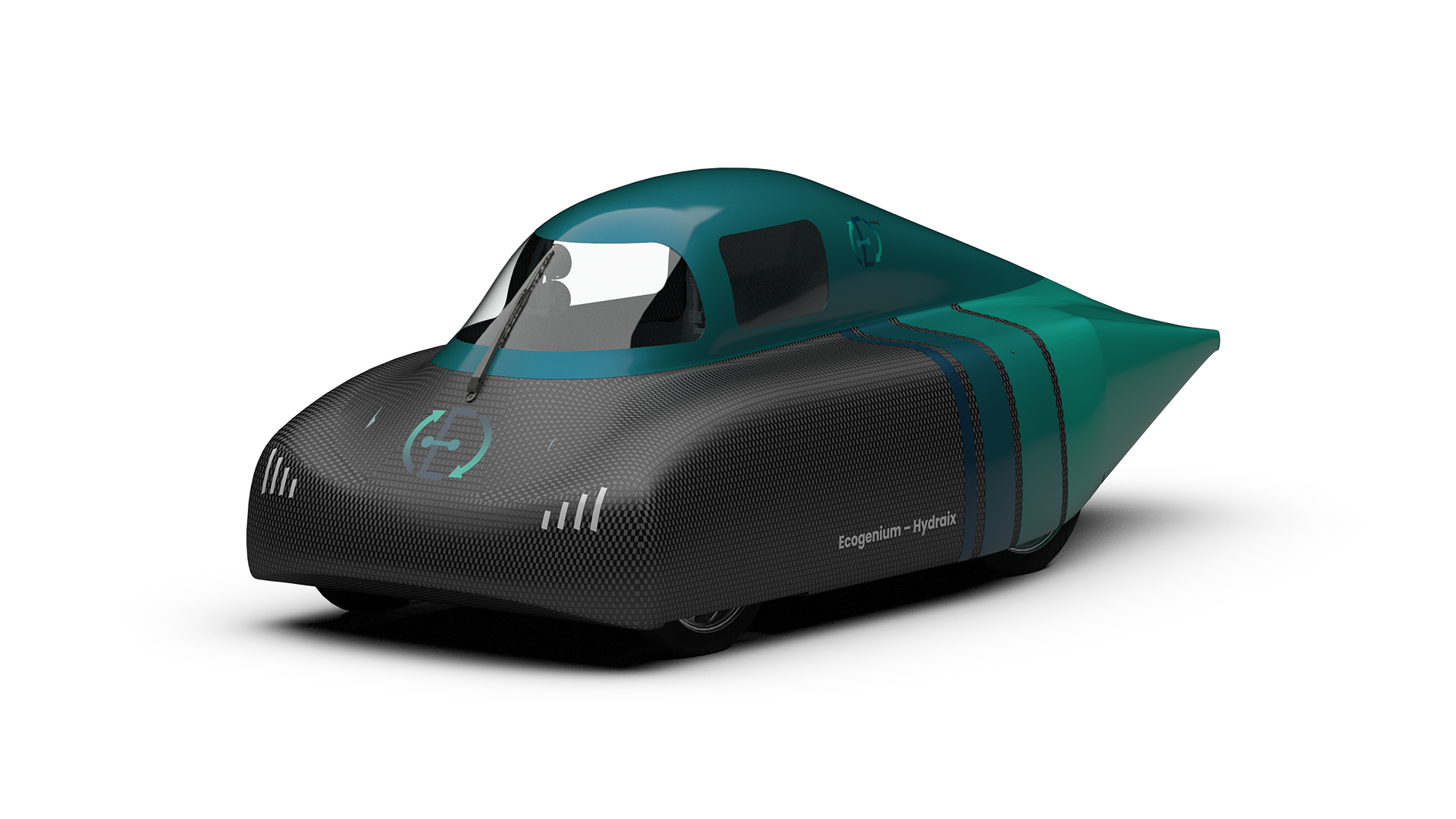

Hydraix I

High efficient urban concept fuel cell vehicle prototype

Our competitor for the Shell Eco-Marathon 2023

The idea of this project is to build a concept car, that is reduced on main specifications and could suit urban driving mobility needs for one person. This vehicle was designed to consume as little energy as necessary. In addition to specially designed system components, a digital driving strategy has been developed to optimize driving performance on the track. For further optimization, supercapacitors were added to the system to provide temporary energy storage.

Quick facts:

- weigth: 110 kg

- max speed: 40 km/h

- energy conversion trough 1 kW air cooled PEM fuel cell

- consumption rate: 83.3 g/100km

- motor power: 2 x 380 W

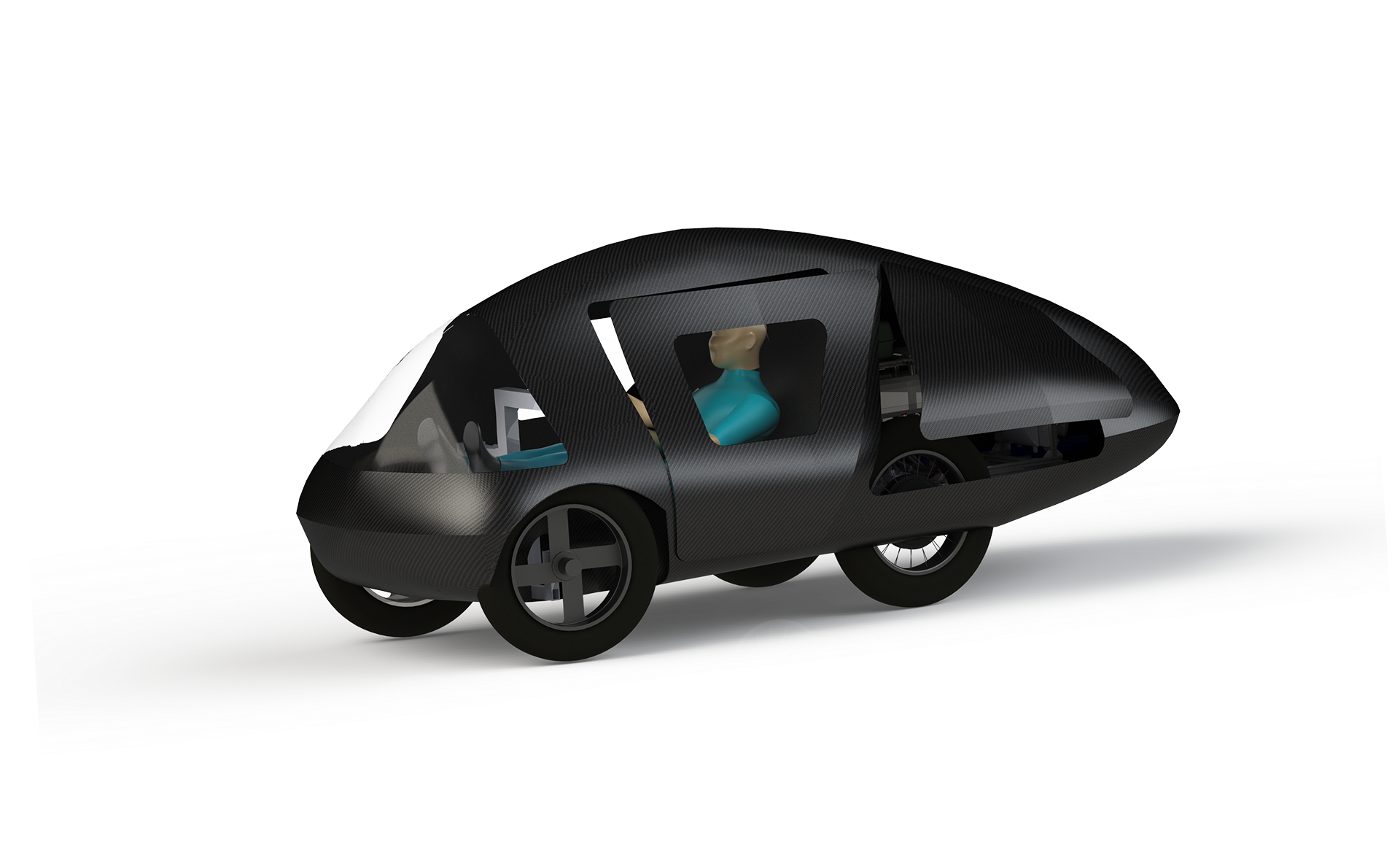

Big step up from Charlemagne

- weigth: 225 kg

- max speed: 55 km/h

- energy conversion trough 3 kW liquid cooled PEM fuel cell

- consumption rate: 374 g/100km

- motor power: 2 x 1 kW

Vehicle highlights

Carbon Chassis as the Base

As a foundation, we simulated a chassis optimized for our specific requirements and loads out of different materials. Our choice was a carbon foam sandwich material. Attached to this chassis are all the further components of the car, such as the wheel suspension, steering, electrical system, and the fuel cell system. The modular design of our vehicle allows for easy maintenance and upgrades.

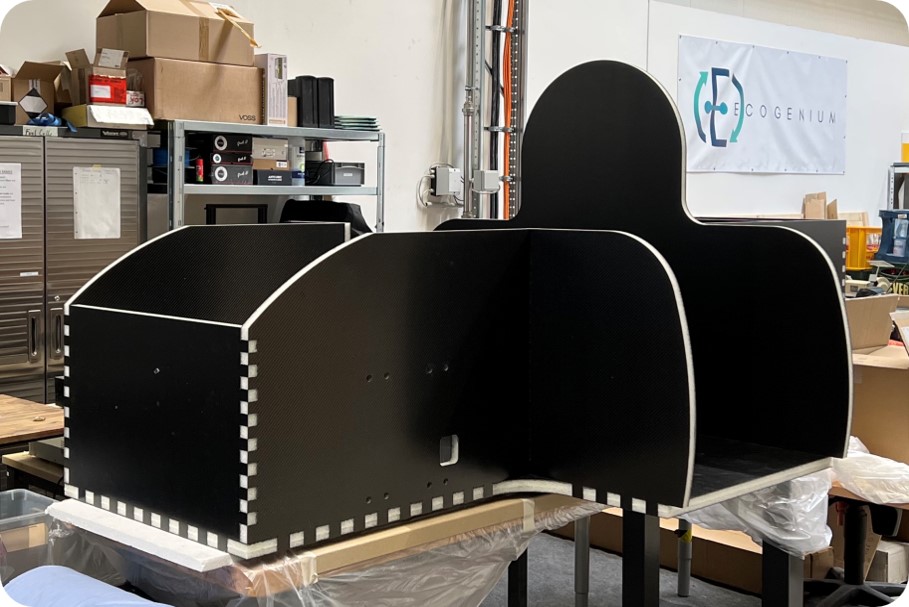

Carbon Aeroshell with Minimal Drag

To minimize drag, our vehicle’s design is refined through aerodynamic simulations. The manufacturing process, carried out entirely in-house, involves milling molds from epoxy blocks, followed by glass fiber layup for creating a precise negative tool, and finally, a carbon layup for the structure. This process is divided between two molds for the upper and lower parts, streamlining production and ensuring a high-quality finish, underscoring our commitment to innovation and efficiency.

High Efficient Motor and Transmission

Fuelcell system

Electric System

Controlling and Driving Strategy

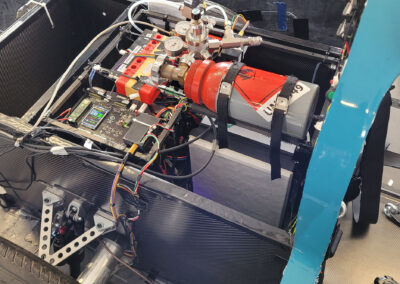

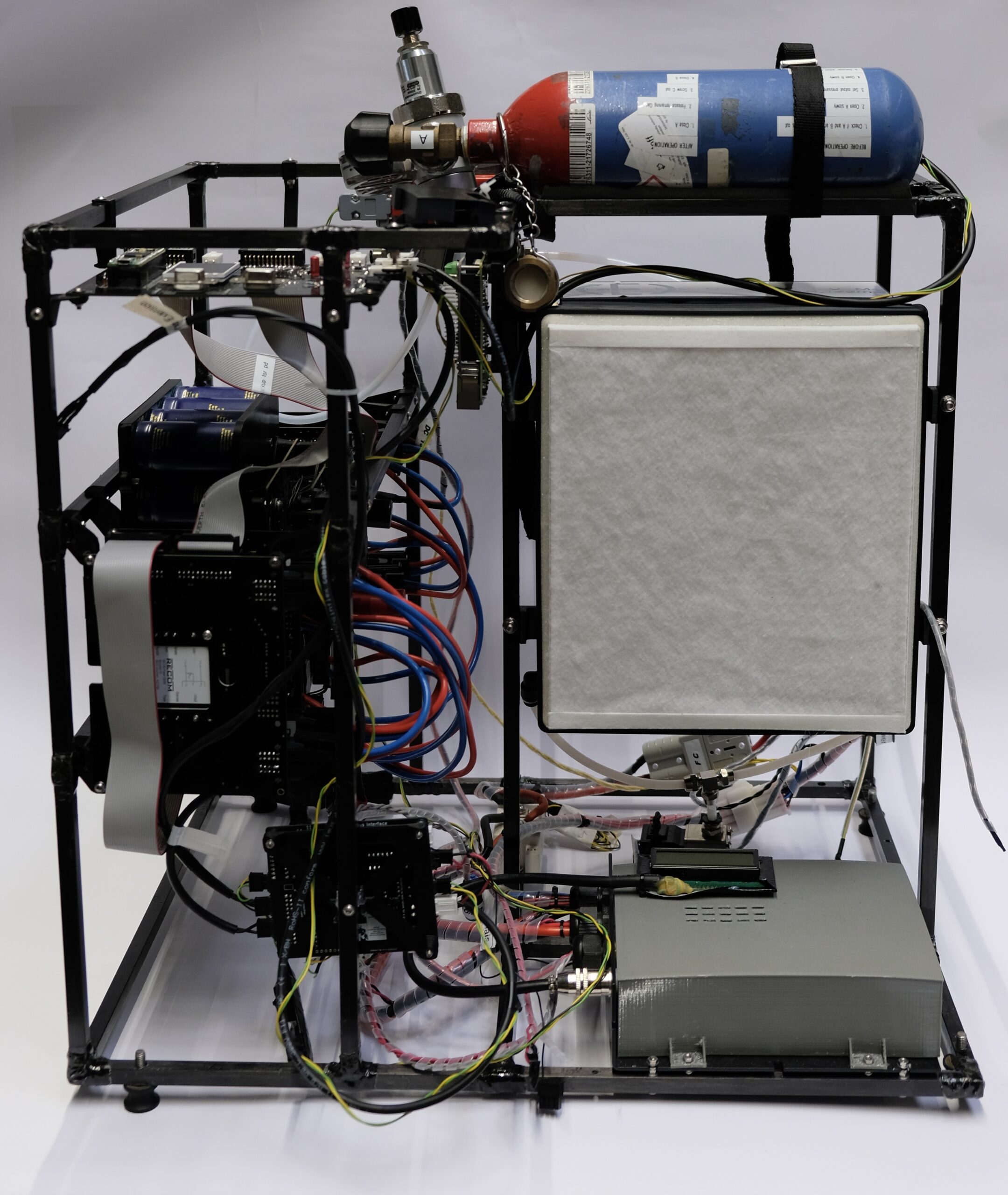

This system integrates a 1 kW air cooled fuel cell into a directly controllable hybrid system.

The fuelcell system in 3D

In-house Developments Highlights

Atava

Control Hardware

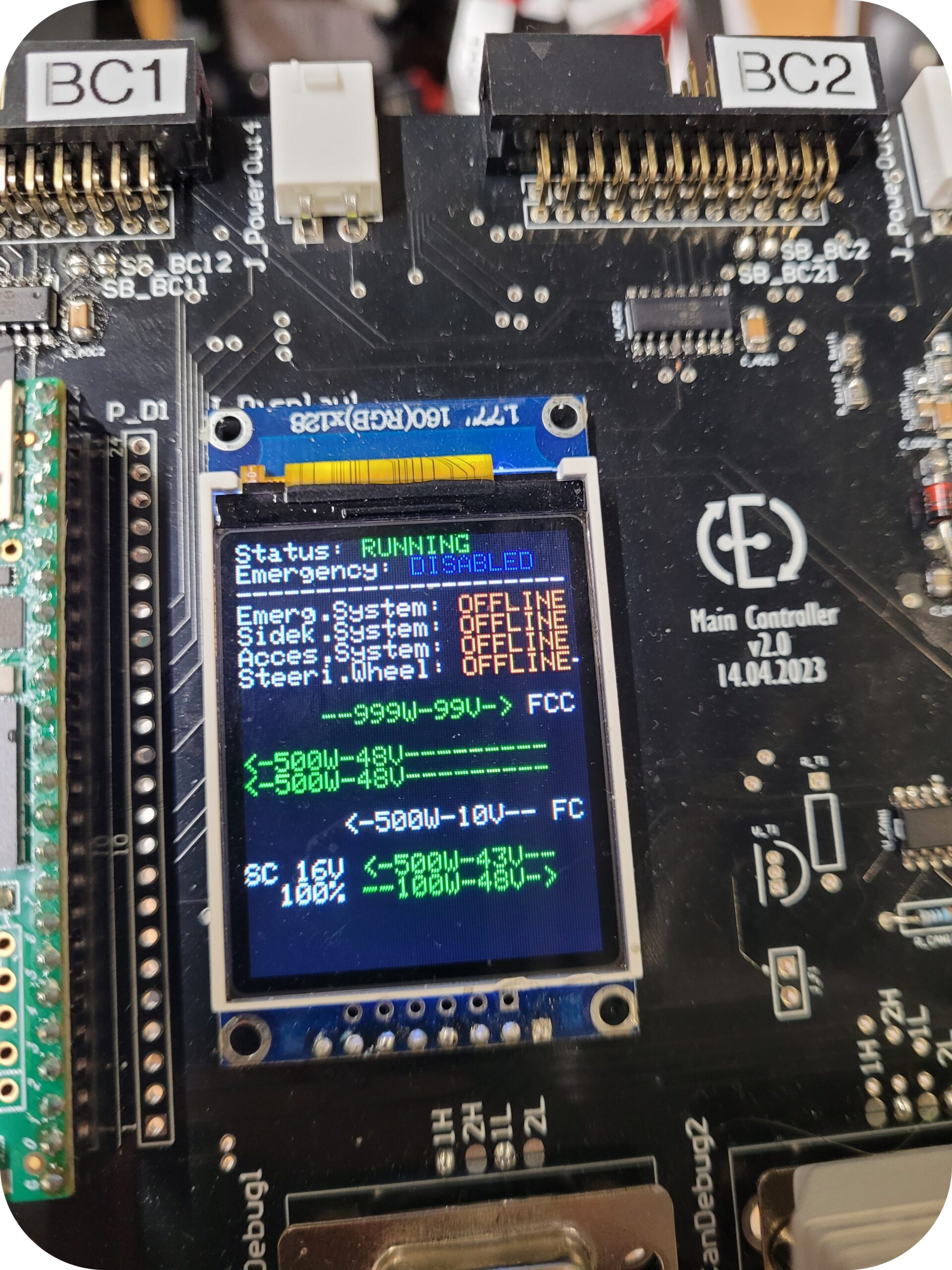

Hydraix I has two control units. The Bus Interface and the Main Controller.

In order to streamline the PCB design process, commonly required functions such as DCDC converters, Can communication, power measurement or a microcontroller have been incorporated into the Bus Interface.

Hydraix I contains a total of 3 Bus Interfaces with different self designed shield PCBs.

The heart of the control system is our main controller, which uses a Teensy 4.1 to run our strategy, controls all the other Bus Interfaces via CAN and directly controls our power system.

It also allows easy debugging, either via the display or by connecting a CAN module to it.

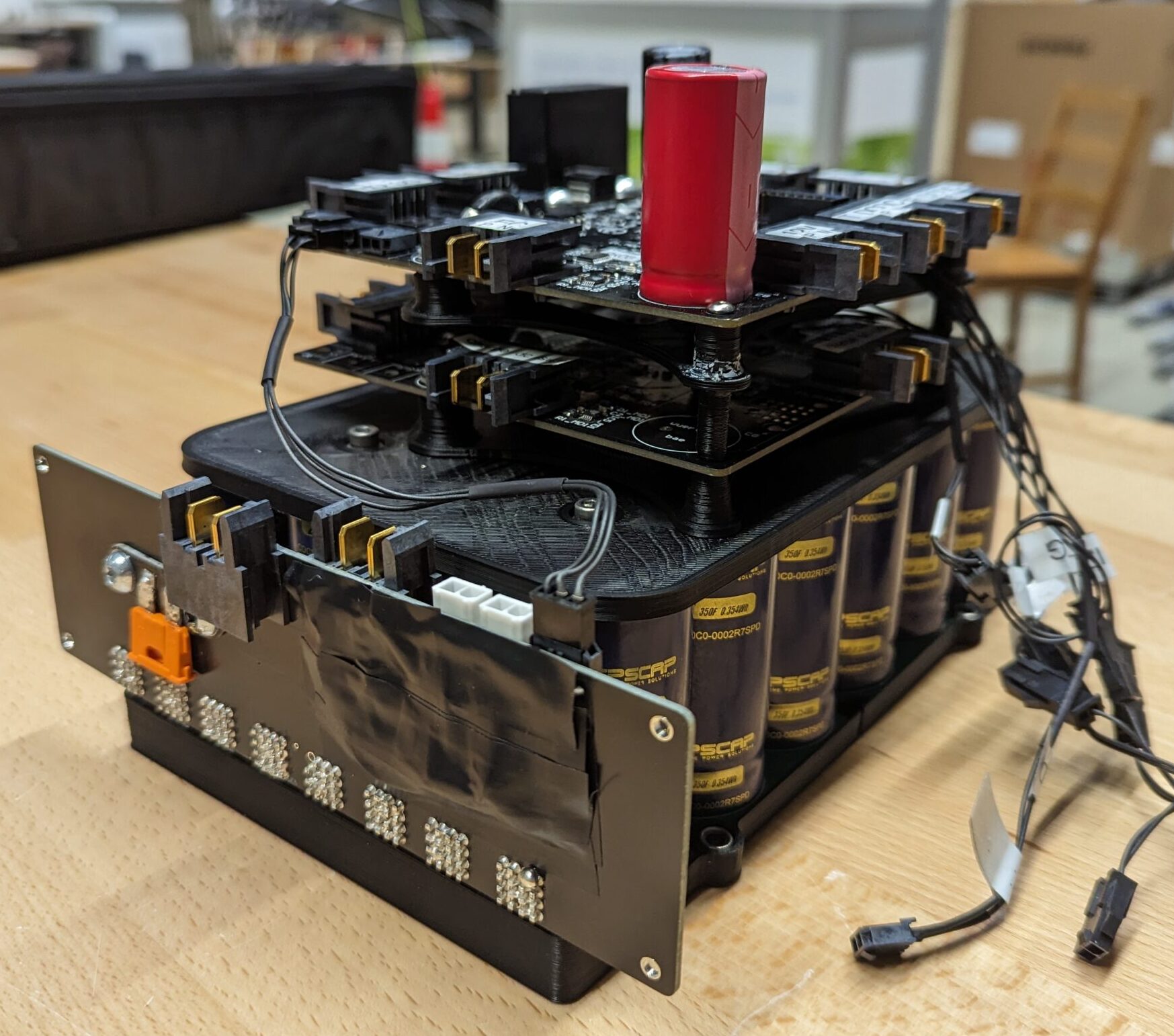

Hybrid Supercaps System

To balance out peaks and valleys in power demand, we developed a system that is capable of storing energy in super-capacitors and consequently releasing it. Combining the two energy sources takes a bit of effort in controlling, which we developed detailed models and strategies for. This makes Hydraix a hybrid vehicle.

Steering Wheel

Our steering wheel is more than just a part that steers our car. With the steering wheel, you are able to control all the settings that are needed to drive the car on the track. You set the throttle, activate / deactivate the manual or automatic driving mode, control all the lights and see the actual energy of our supercapacitors. You will also see the load that is provided by the fuel cell itself.

To achieve all that, we had to build our steering wheel completely by ourselves. The main structural part is a carbon backplate that gives excellent stability. On top of that is our 3D-printed cover, which holds the LCD and the required buttons. Our throttle is placed on the back for ergonomic handling while driving. All the signals come together in a self build printed circuit board, which then transmits the data to the other hardware components.